So, which embroidery product is right for you? We’ve put together this comparison to help guide you to the right solution.

Recommended Mighty Hoop Sizes for Popular Placements and Garments

Whether you’re stitching a small logo or a large back design, choosing the right Mighty Hoop can make embroidery smoother and more efficient. That’s why we created this guide outlining our recommended Mighty Hoop sizes for popular placements and garments.

Note: Magnetic Hoops are compatible with tubular embroidery machines. Be sure to confirm your machine’s compatibility before purchasing. The recommendations in this guide are based on popular usage. Your specific Mighty Hoop needs may vary. Also, keep in mind that your design size should be approximately 1” smaller than the size of your hoop.

Mighty Hoop Size Recommendations by Placement:

Full Back/ Jacket Back

Full back embroidery is commonly used on the back of sweatshirts and jackets for larger designs. Mighty Hoops, such as the 8 x 13” or the 11 x 13”, provide adequate sewing area for large embroidery.

Recommended Mighty Hoop Sizes: 8 x 13″, 11 x 13″

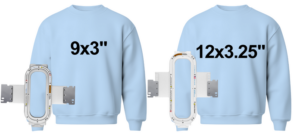

Sleeves

Sleeve embroidery typically involves narrow design areas that  require slimmer hoops like the 9 x 3” and 12 x 3.25” Mighty Hoop. Choosing the right magnetic hoop size helps prevent sleeves from stretching. Smaller Mighty Hoops also allow room for the bobbin arm to move freely. For best results, we recommend using a Backing Holder to help keep the stabilizer in place while hooping.

require slimmer hoops like the 9 x 3” and 12 x 3.25” Mighty Hoop. Choosing the right magnetic hoop size helps prevent sleeves from stretching. Smaller Mighty Hoops also allow room for the bobbin arm to move freely. For best results, we recommend using a Backing Holder to help keep the stabilizer in place while hooping.

Recommended Mighty Hoop Sizes: 9 × 3″, 12 × 3.25″

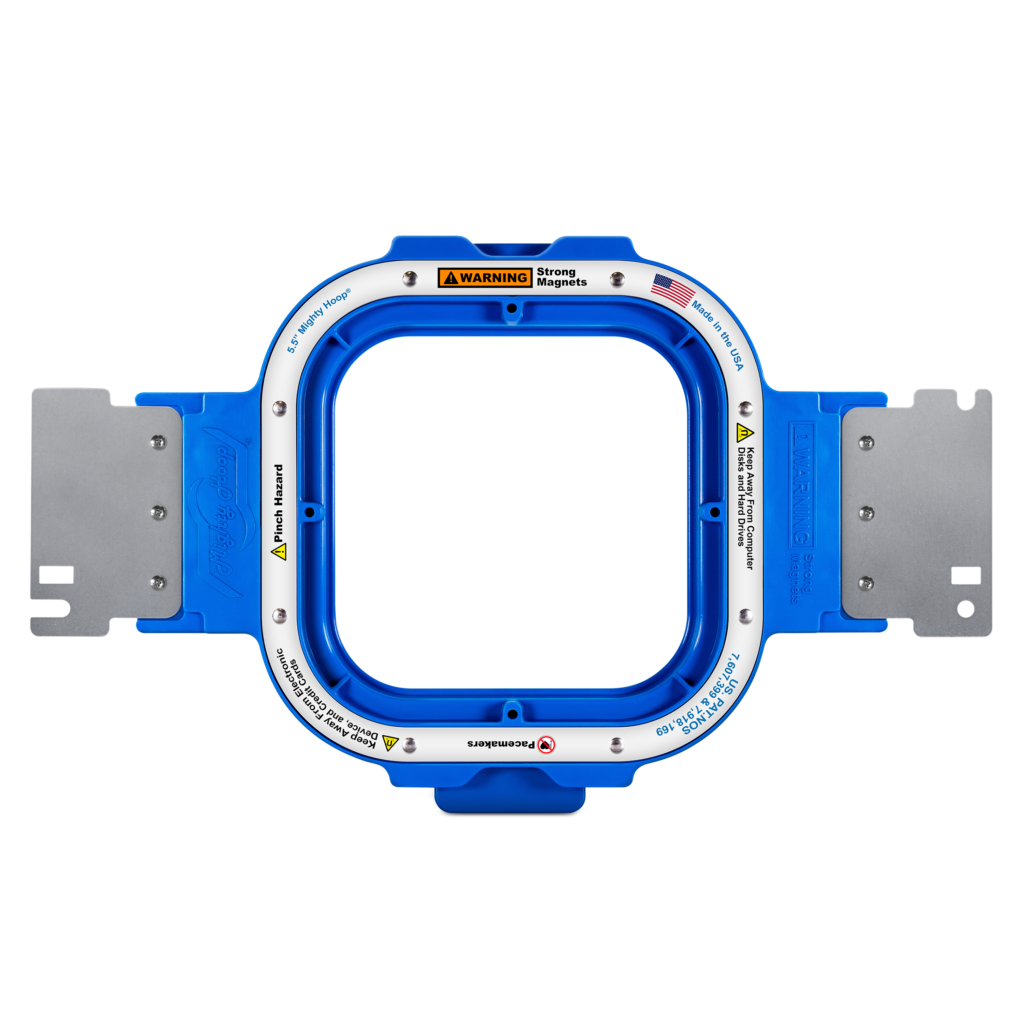

Left or Right Chest

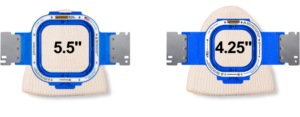

Left and right chest placements are among the most popular embroidery locations for polos, shirts, and sweatshirts. The average left chest design size is between 3″ – 4.5″, making the 5.5” or 6.5″ Mighty Hoop the perfect size for this application.

locations for polos, shirts, and sweatshirts. The average left chest design size is between 3″ – 4.5″, making the 5.5” or 6.5″ Mighty Hoop the perfect size for this application.

Recommended Mighty Hoop Size: 5.5”, 6.5″

Mighty Hoop Size Recommendations by Garment:

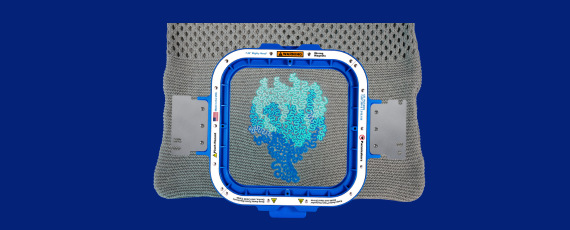

Beanie

Typically, embroidery designs on beanies are smaller. Using the smallest hoop possible for your design guarantees taut tension while not over stretching the beanie which can cause design distortion. The 4.25″ and 5.5″ Mighty Hoops are the most preferred sizes by embroiderers for beanies.

Recommended Mighty Hoop Sizes: 4.25″, 5.5″

Sweatshirts and Hoodies

Sweatshirts and hoodies are popular for larger embroidery designs. The 8×13″ Mighty Hoop is a great size for these designs, including the very popular applique designs.

Recommended Mighty Hoop Size: 8 × 13″

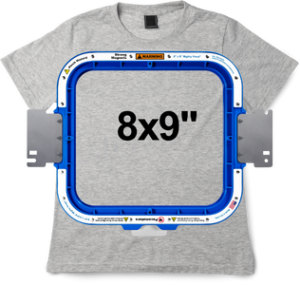

Youth Shirts

Youth garments require hoop sizes that match smaller embroidery areas while maintaining proper tension. Using the correct size helps reduce bunching and improves stitch quality. The 8×9″ Mighty Hoop works great with toddler and youth sizes. If you are embroidering infant and newborn shirts, we would recommend the 5.5″ or 7.25″ Mighty Hoop to prevent stretching.

improves stitch quality. The 8×9″ Mighty Hoop works great with toddler and youth sizes. If you are embroidering infant and newborn shirts, we would recommend the 5.5″ or 7.25″ Mighty Hoop to prevent stretching.

Recommended Mighty Hoop Size: 8 × 9″

Bodysuits

Bodysuits feature smaller embroidery widths but offer the opportunity for longer designs. The 9×5″ and 9×6″ Mighty Hoops both allow plenty of spa ce for your creative infant and young toddler designs. Smaller Mighty Hoop sizes allow for accurate placement and accurate stitching without distorting the garment.

ce for your creative infant and young toddler designs. Smaller Mighty Hoop sizes allow for accurate placement and accurate stitching without distorting the garment.

Recommended Mighty Hoop: 9×5”, 9×6″

Choosing the right Mighty Hoop size is very important. The right magnetic hoop size will help you obtain clean, consistent embroidery results, while also making the hooping process easier. Remembering to choose the embroidery hoop closest to your design size will help eliminate puckering, uneven tension, and distorted stitches. This guide was designed to help guide you in choosing the correct size Mighty Hoop for your design placement and garment. We offer a variety of magnetic Mighty Hoop sizes to fit your individual needs.

If you’re interested in exploring additional Mighty Hoop sizes or need help confirming machine compatibility, please contact us. If you are interested in embroidery design placement guides when using the HoopMaster Hooping System, click here.