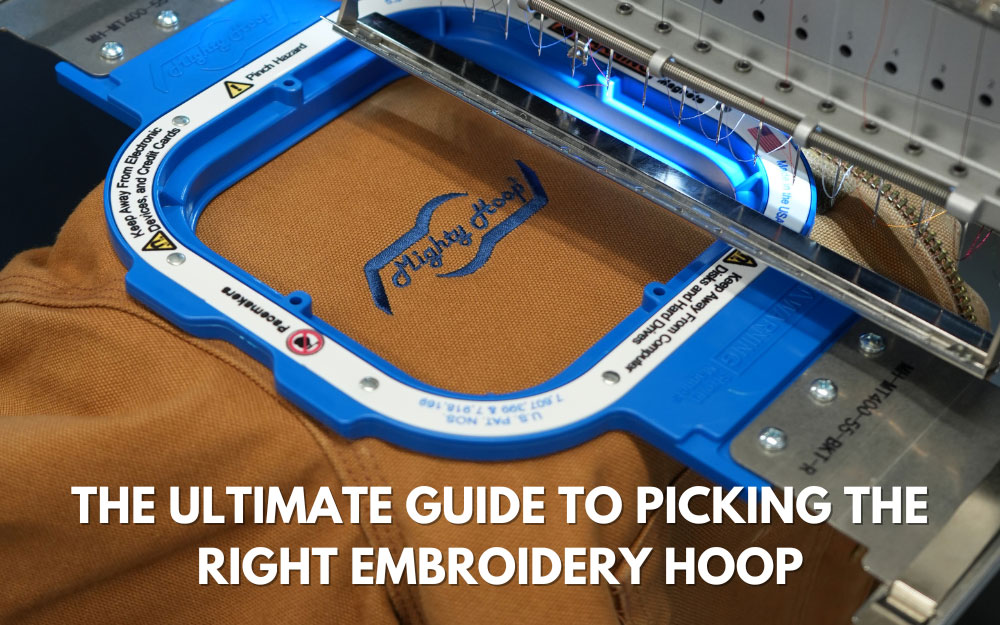

So, which embroidery product is right for you? We’ve put together this comparison to help guide you to the right solution.

Velveteen Blanket Embroidery Tutorial (Step-by-Step with Mighty Hoop)

Looking to embroider a thick, luxurious velveteen blanket with professional results? In this step-by-step tutorial, we’ll show you how to hoop and stitch a blanket using the HoopMaster Station, Adjustable Fixture, and a 4.25×13” Horizontal Mighty Hoop. This method is perfect for thick or delicate materials and tubular embroidery machines.

🎥 Watch the full video tutorial below

Tools Used in This Tutorial

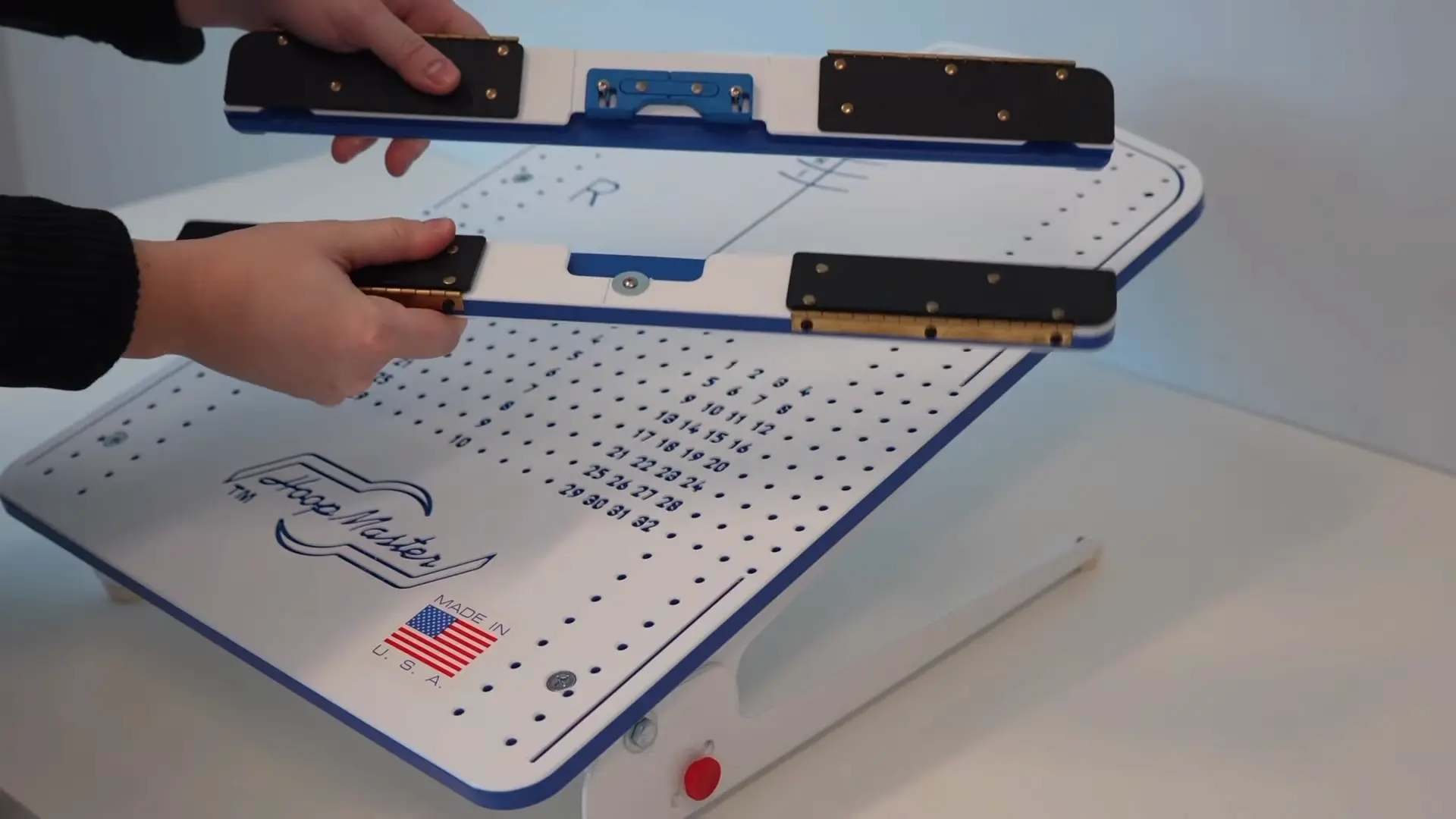

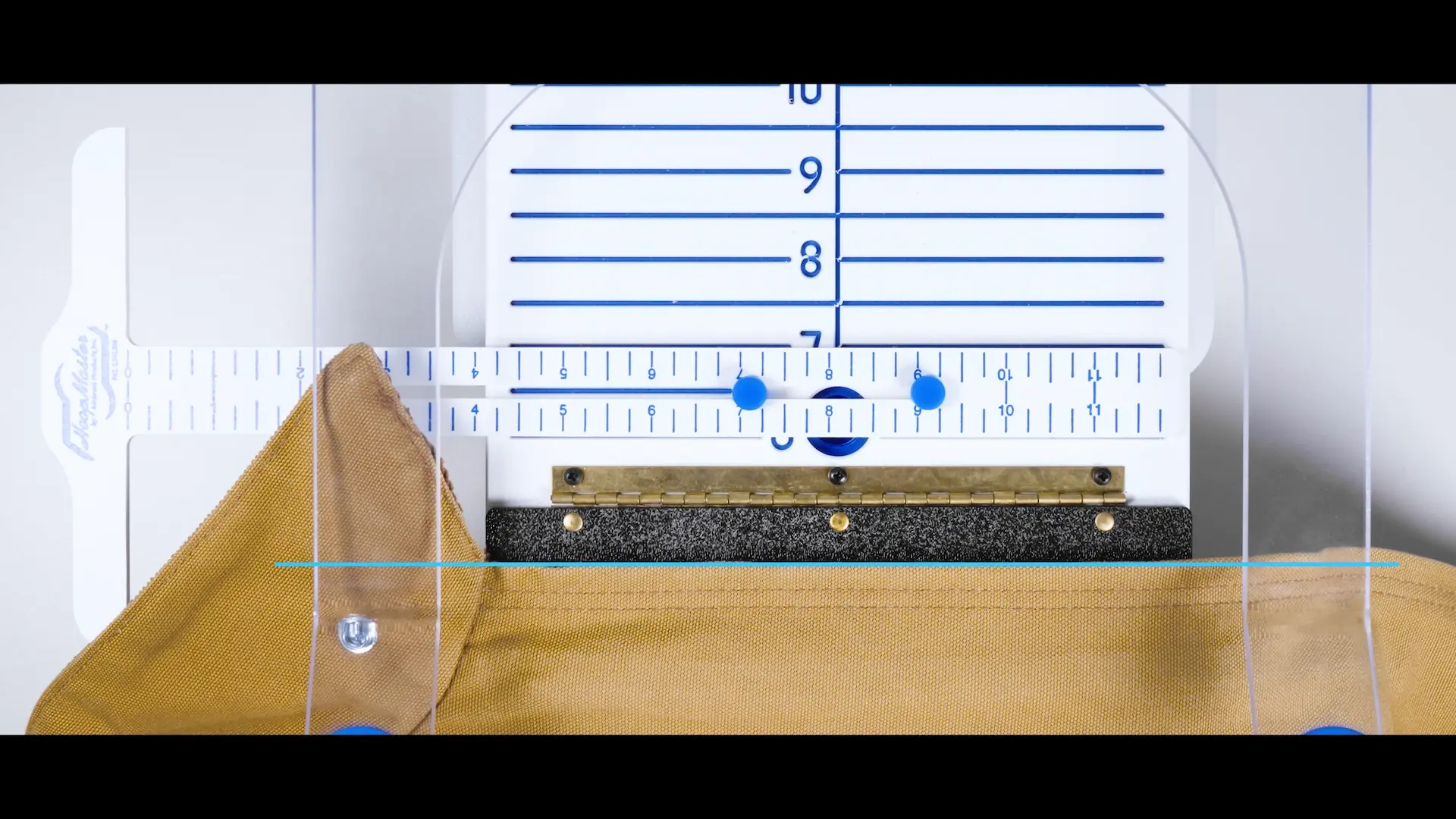

Step 1: Set Up Your HoopMaster Station

Start by adjusting the HoopMaster Station to lie flat (you can hoop at an angle, but flat is easier for thick fabrics like blankets).

-

Flip the station over.

-

Loosen the thumbscrews and wingnuts.

-

Push the legs down until flat.

-

Tighten everything back in place.

-

Flip the board right-side-up.

Place the Adjustable Fixture on the station. We positioned ours above the number “8” on the board for reference.

Step 2: Secure Your Mighty Hoop

We’re using the 4.25×13” Horizontal Mighty Hoop, ideal for tubular embroidery machines. If you’re unsure whether it fits your machine, check our website or give us a call.

To install:

-

Insert the bottom hoop ring into the lower fixture.

-

Slide the top piece of the fixture down to hold it snugly.

-

Open the magnetic flaps for hooping access.

Step 3: Choose the Right Stabilizers

We used:

-

Two layers of tearaway stabilizer (for stability and easy removal).

-

One layer of water-soluble stabilizer on top (prevents stitches from sinking into soft fabric).

Because the back of the blanket will be visible, tearaway gives a cleaner finish than cutaway on this thin material.

Step 4: Mark Your Design Placement

For accurate placement:

-

Use placement dots to mark the center.

-

Measure from the bottom of the rope design to the edge of the blanket (ours was ~11″).

-

Place your center mark at around 5.5″, then adjust it to sit perfectly within the rope’s knot.

-

Align this mark with the centerline of the station.

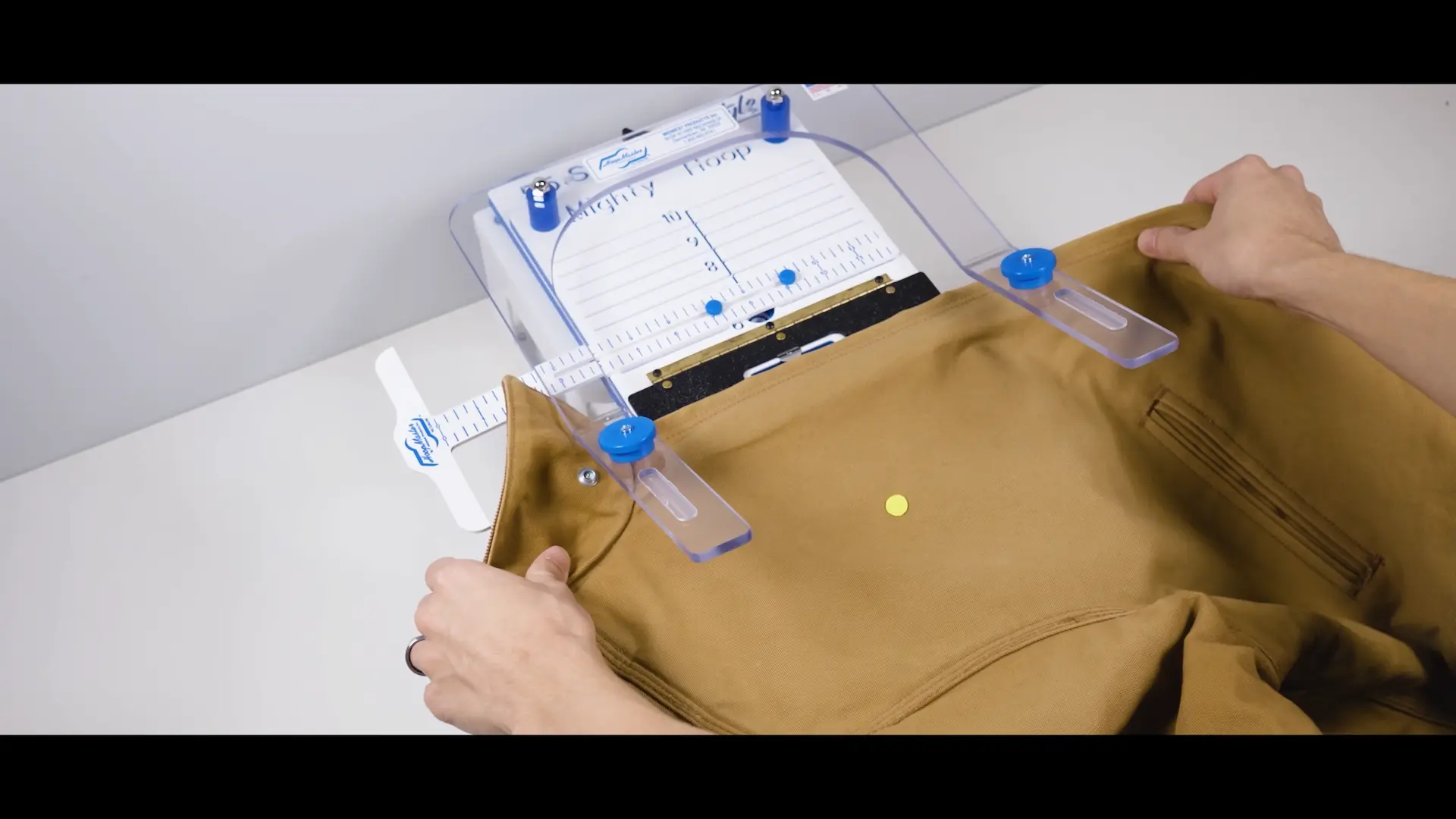

Step 5: Hooping the Blanket

Once your stabilizers are clipped in:

-

Pull the blanket onto the station.

-

Align the placement mark with the station’s centerline.

-

Feel for the Mighty Hoop’s inner ring to make sure it’s centered.

-

Remove the dot and lay the water-soluble stabilizer over the hoop area.

-

Press the top ring of the Mighty Hoop into place.

Step 6: Embroidering the Design

-

Mount the hooped blanket onto your machine.

-

Drape the rest of the blanket over a chair to relieve arm weight.

-

Flip your design 180° before stitching (since it’s hooped upside-down).

-

Always run a trace to ensure your design fits inside the hoop.

Step 7: Cleanup and Finishing Touches

Once embroidery is complete:

-

Remove the hoop from your machine.

-

Tear away the water-soluble stabilizer.

-

Use tweezers or steam to remove any small bits stuck between letters.

-

Tear away the stabilizer on the back.

-

Trim any loose threads.

And that’s it — your embroidered velveteen blanket is complete!

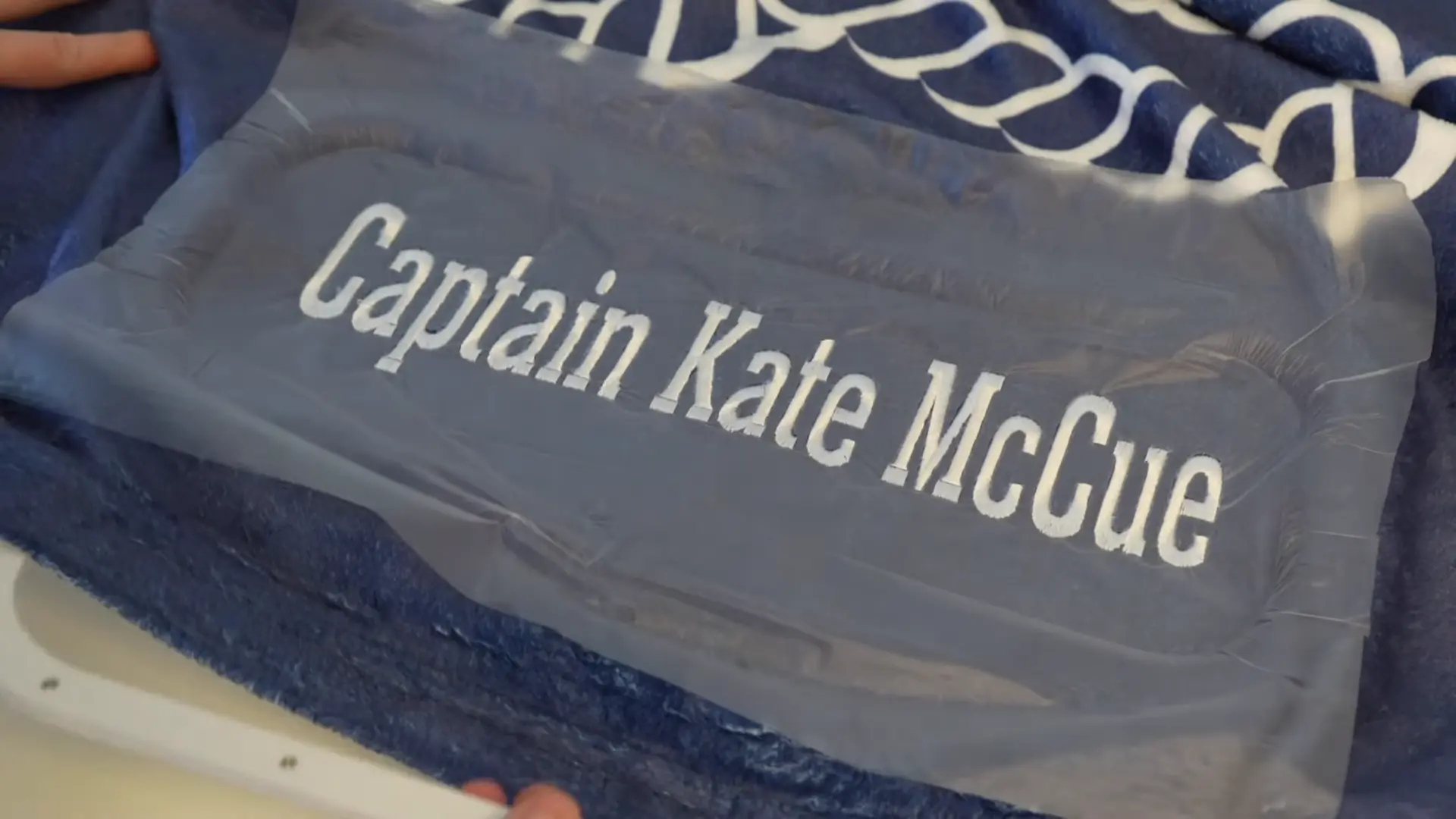

Whether you’re personalizing a gift or tackling a thick fabric project, the HoopMaster and Mighty Hoop system makes the hooping process fast, clean, and frustration-free. This tutorial featured a special gift for Captain Kate McCue, but the techniques apply to any embroidery project involving dense designs and soft materials.

🛳️ Going on a cruise? A custom embroidered blanket makes a fantastic gift!

Need Help or Want to Order?

📞 Call us: (262) 257-0930 (Mon–Fri, 8:00am–4:30pm CST)

🌐 Shop all HoopMaster & Mighty Hoop products