Introduction:

Midwest Products, Inc. is the world leader in commercial embroidery hooping systems. As the sole manufacturer and innovator in the embroidery industry and best known for developing the HoopMaster Station and magnetic embroidery hoops called Mighty Hoop. These embroidery tools have revolutionized hooping by providing precision, efficiency, and ease of use. Whether you are a small business or a large production facility, these products simplify the embroidery process, ensuring consistent hooping results every time.

What is the HoopMaster Station?

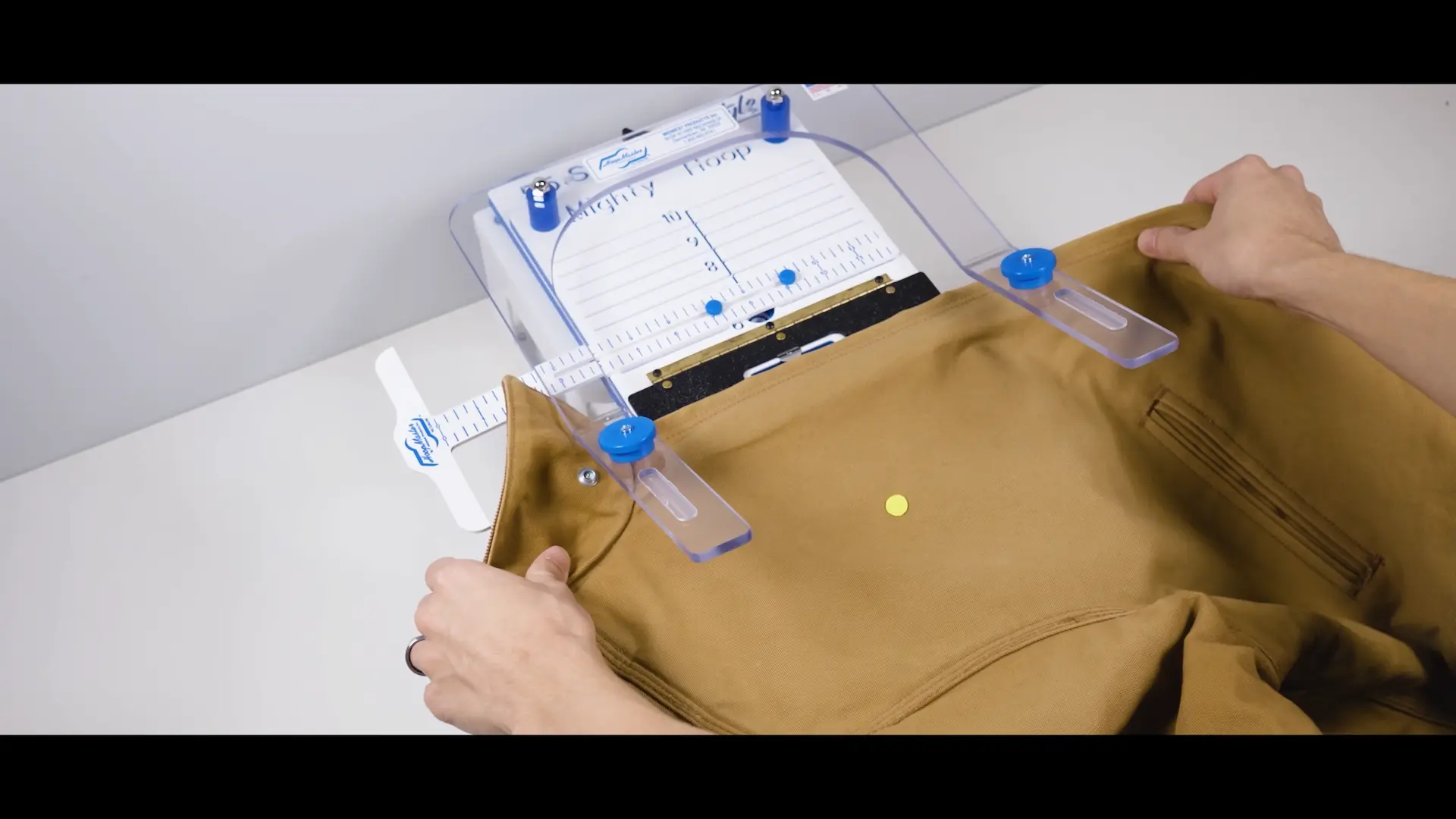

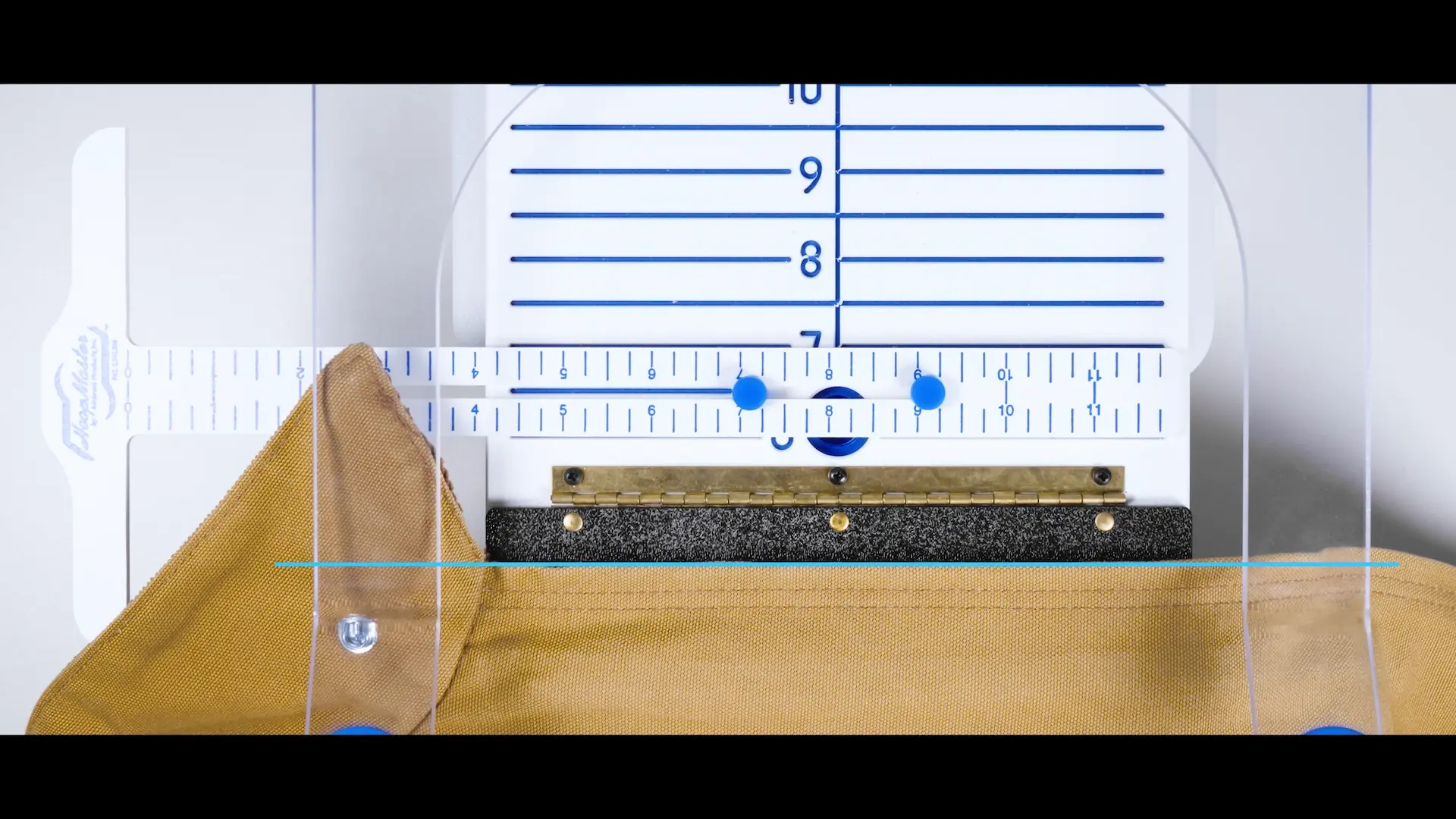

The HoopMaster Station is a specialized hooping board designed to streamline the embroidery setup process. It provides a structured platform that ensures accurate and repeatable placement of garments in embroidery hoops. This tool eliminates guesswork, reduces errors, and speeds up production, making it an essential investment for embroiderers seeking consistency and efficiency. Watch this video to understand more about the function of the letters, numbers, and holes on the Station. https://youtu.be/TybpAhjqTgQ (Starts a 01:01)

What are Mighty Hoops?

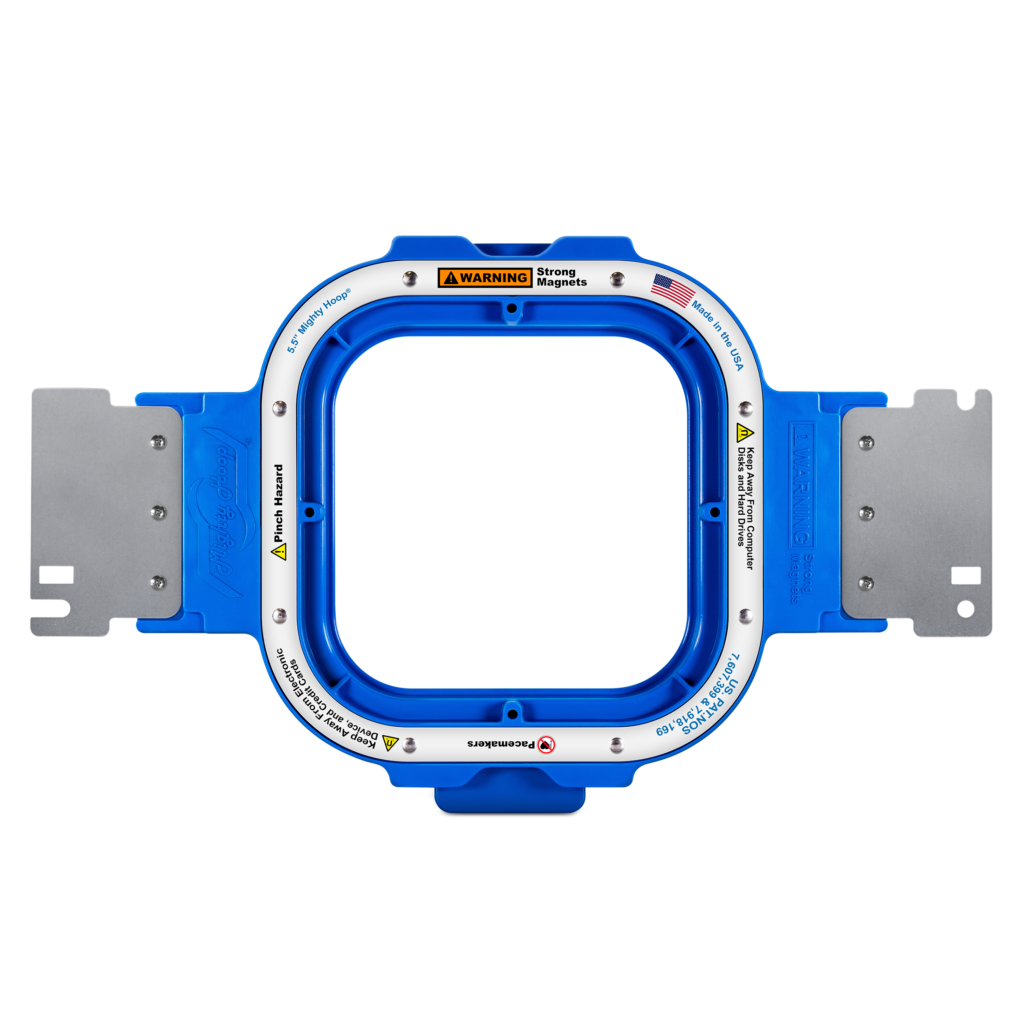

A Mighty Hoop is a magnetic embroidery hoop designed to hold garments securely without the need for excessive manual tightening. Unlike traditional hoops that rely on tension and clamping pressure, Mighty Hoops use powerful magnets to hold fabric in place, significantly reducing strain on the user’s hands and ensuring uniform tension for high-quality embroidery results.

How Magnetic Hoops Work:

Magnetic hoops aka Mighty Hoop function by utilizing strong embedded magnets that clamp fabric between the top ring and bottom ring of the hoop. The magnetic force securely holds the material without causing stretching or distortion, making it ideal for various fabric types, including thick Carhartt jackets, leather, delicate lace, silk, and everything in between. This innovative design allows for easy hooping and removal, reducing the physical effort required in traditional hooping methods.

Benefits of Using Mighty Hoops:

Mighty Hoops offer numerous benefits over conventional hoops, including ease of use, reduced operator fatigue, and improved hooping accuracy. The strong magnetic hold ensures that fabric stays in place, preventing shifting during embroidery. Additionally, the hoop’s design minimizes hoop burn, making it a preferred choice for embroiderers working with delicate materials. These advantages contribute to faster production times and more consistent embroidery quality.

Mighty Hoops and Tubular Embroidery Machines:

Mighty Hoops are only compatible with tubular embroidery machines. A tubular embroidery machine is a type of embroidery machine designed to accommodate open-ended garments such as shirts, jackets, and bags by allowing free movement of the fabric around the hoop. Unlike flatbed embroidery machines, which require fabric to be clamped flat, tubular machines allow for more versatility in hooping and stitching.

There are many different brands of tubular embroidery machines, including:

- Tajima

- Barudan

- Brother

- Baby Lock

- Happy

- SWF

- ZSK

- Melco

- Ricoma

- Bai

- Bernina

- Avance

- Smartstitch

- Toyota (and so much more!)

Depending on your machine brand and model, we will install a specific style of brackets on your Mighty Hoops to ensure they fit properly. Each machine requires uniquely designed brackets for seamless compatibility, allowing the hoop to be securely attached and function correctly with your embroidery machine.

View our entire brand machine list here: https://hoopmaster.com/products/mighty-hoop

Don’t see your machine brand? Email info@hoopmaster.com

Visit this link to see what we offer for Brother and Baby Lock Flatbed Embroidery machines. https://hoopmaster.com/products/hoopmaster-home-edition

Reducing Hoop Burn:

Hoop burn occurs when excessive pressure from traditional hoops leaves marks or indentations on the fabric. Mighty Hoops significantly reduce hoop burns because they do not require tight clamping. The magnetic hold applies even pressure without crushing fibers, making it ideal for sensitive materials such as fleece, silk, and performance fabrics.

Enhancing Efficiency:

Efficiency is key in any embroidery operation, and Mighty Hoops contribute by reducing setup time and minimizing rework. The quick and easy hooping process allows embroiderers to complete more orders in less time. The combination of HoopMaster Station, Mighty Hoop Fixtures and Mighty Hoops creates the perfect hooping set-up.

Basic Operation:

Using Mighty Hoops to hoop your garments is simple. The fabric is placed between the two magnetic hoop components, which snap together securely. The hoop is then positioned in the embroidery machine’s frame, and the design is stitched. Once completed, the hoop can be easily separated, and the finished product removed with minimal effort. This process eliminates the need for manual tightening, making it accessible for users of all experience levels.

User Precautions:

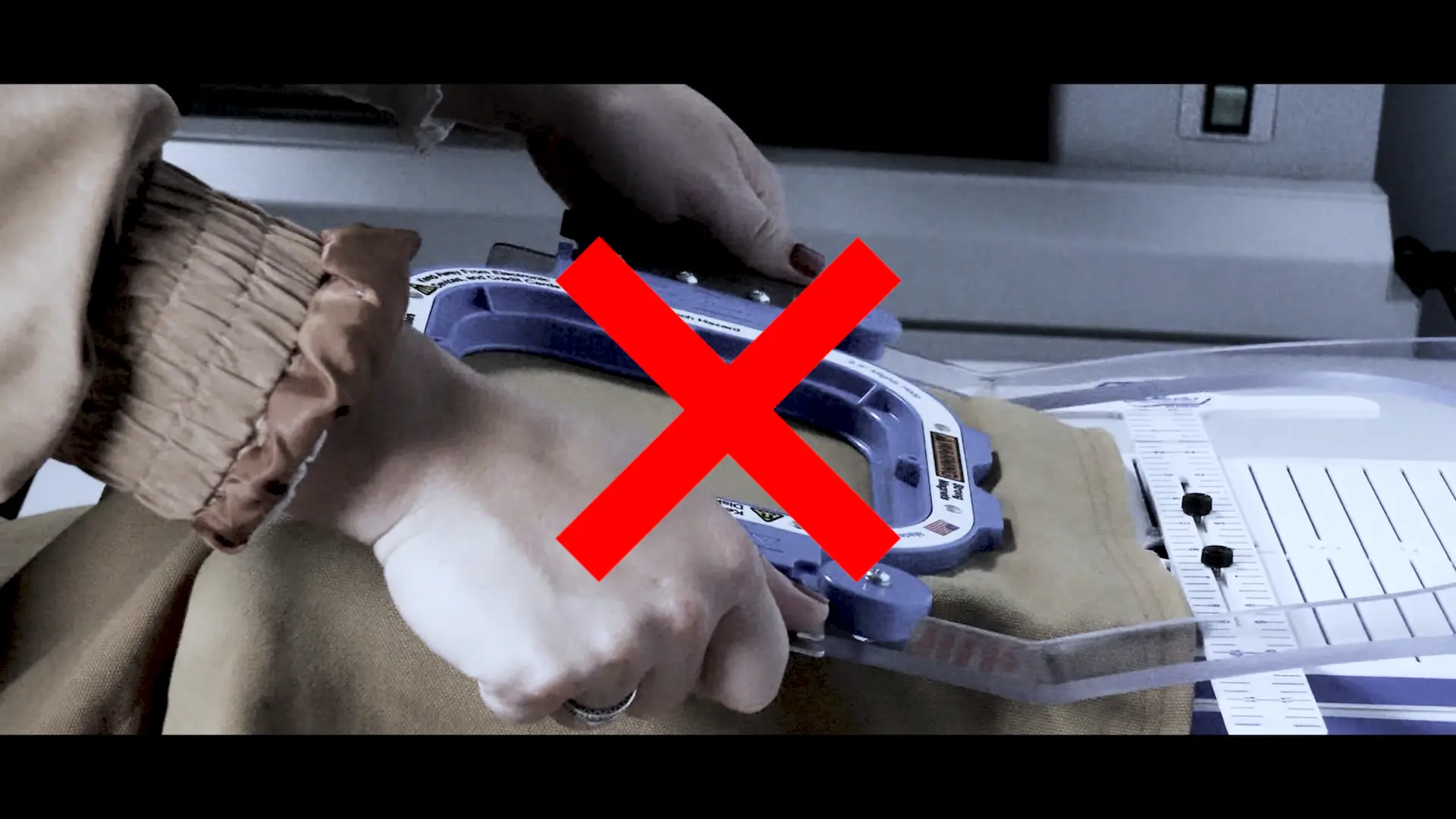

While Mighty Hoops offer numerous advantages, users should exercise caution due to the strength of the magnets. Handling the hoops carefully is essential to avoid finger pinching or accidental snapping. Additionally, individuals with pacemakers or medical implants should consult their healthcare provider before using magnetic hoops due to potential interference. View our warning list here: https://hoopmaster.com/support/mighty-hoops-magnetic-hoops-safety-warning

Conclusion:

Midwest Products, Inc. continues to set industry standards with its innovative embroidery hooping systems. The HoopMaster Station and Mighty Hoops have transformed the way embroiderers work by improving accuracy, efficiency, and user comfort. Whether you are an experienced embroiderer or just starting, investing in these high-quality American made tools can elevate your embroidery projects, making the process faster, easier, and more professional.